Introduction

In industrial projects, a display is more than a nice visual element. It must run 24/7, survive heat, cold, vibration, sunlight, and dust, and keep costs under control.

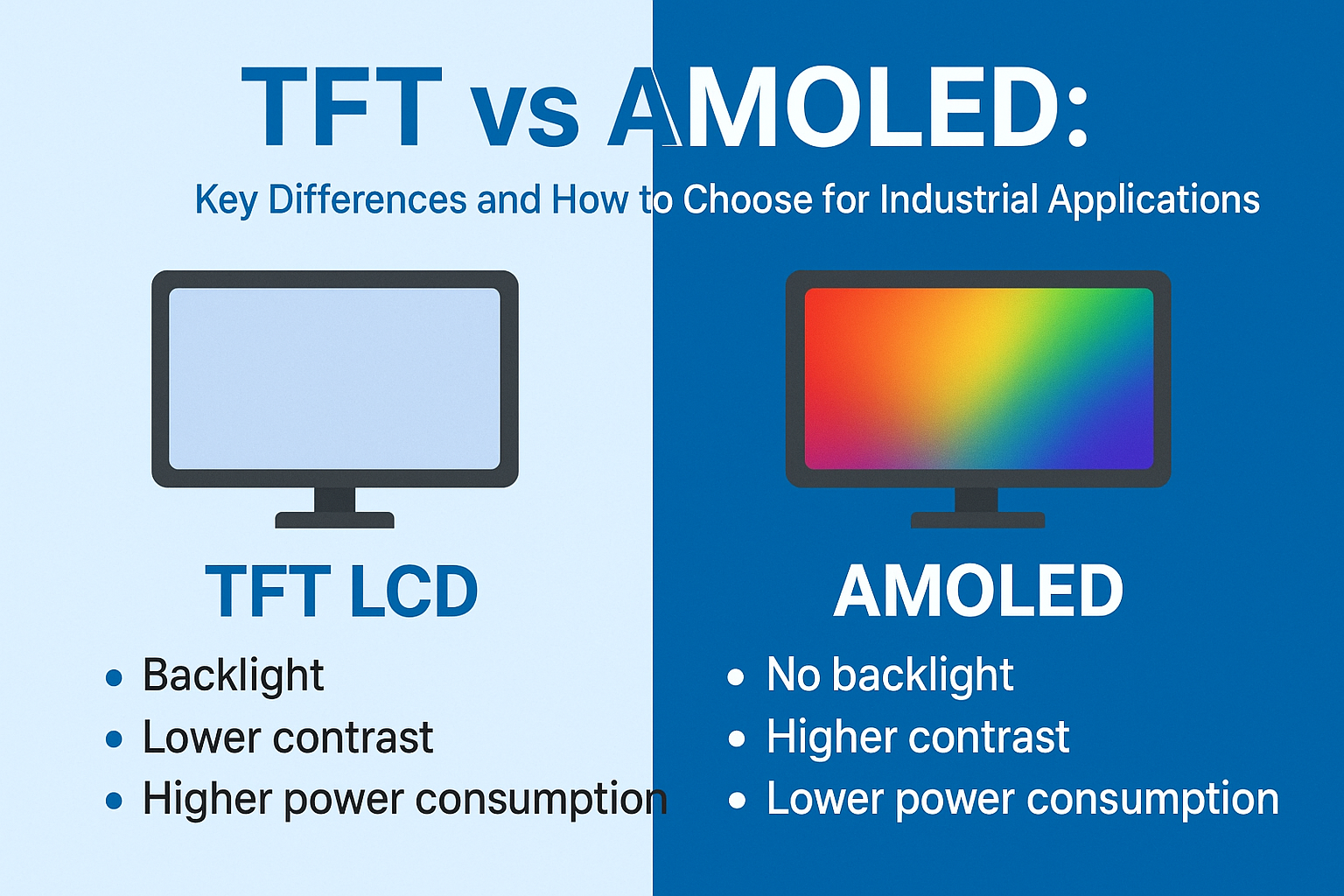

This guide explains the differences between TFT-LCD and AMOLED from an industrial perspective, and shows how to choose the right technology for real projects.

1. Key Specifications Comparison

| Category | TFT-LCD | AMOLED |

| Light Source | Uses a backlight | Each pixel emits light |

| Contrast | Medium, stable | Very high, true black |

| Outdoor Visibility | Very strong with high-brightness (700–2000 nits) and anti-glare options | Weak under strong sunlight; reflection reduces clarity |

| Viewing Angle | Wide (IPS/VA versions) | Wide |

| Response Time | Fast for industrial needs | Extremely fast |

| Power Consumption | Higher with bright UIs (due to backlight) | Lower with dark UIs, but high brightness drains power |

| 24/7 Lifetime | Long and stable | Pixel aging and burn-in risk |

| Burn-in Risk | Very low | High with static UI |

| Environment Durability | Good for shock, vibration, wide temp | Limited industrial-grade options |

| Cost | Lower, stable supply chain | Higher cost, supply fluctuations |

| Customization | Easy (touch, cover lens, coatings) | More complex and costly |

| Typical Industrial Fit | Very strong | Limited, depends on use case |

2. Deeper Analysis for Industrial Needs

1) Outdoor Visibility and Harsh Environments

TFT handles sunlight well. High-brightness backlight, anti-glare coating, and strong cover glass improve readability.

AMOLED struggles under direct sunlight. It needs higher brightness to fight reflections, which speeds up aging.

2) 24/7 Operation and Long Lifetime

TFT runs day and night for many years. Backlight aging is predictable and easy to manage.

AMOLED pixels age faster. Static icons or menus cause burn-in, which is a major problem for long-running HMI devices.

3) Reliability Under Heat, Vibration, and Dust

TFT offers many industrial-grade modules with wide temperature ranges and stronger mechanical structures.

AMOLED has fewer industrial-grade options, and thin flexible structures can fail under long-term stress.

4) Power Consumption

TFT uses more power because the backlight stays on.

AMOLED saves power with dark UIs, but many industrial interfaces use bright backgrounds, so the advantage is not always visible.

5) Cost and Supply Chain

TFT has a mature ecosystem. Prices stay stable, and replacement is easy.

AMOLED costs more, and wide-temperature or rugged versions push the price even higher.

3. How to Choose Based on Real Industrial Scenarios

Scenario A: Outdoor Devices / Public Terminals / Harsh Environments

Choose: TFT-LCD

Bright sunlight, rain, dust, and vibration make TFT the safer choice.

Scenario B: Factory HMI Panels (24/7, Static UI)

Choose: TFT-LCD

HMI screens display the same icons all day. AMOLED burn-in risk is too high.

Scenario C: Medical Monitors / Professional Instruments

Choose: TFT-LCD for long lifetime and stability.

Choose AMOLED only when you need extreme contrast and the interface changes frequently.

Scenario D: Portable Testers / Handheld Devices

Choose: AMOLED if you want high contrast and thin design.

Make sure your UI moves slightly or refreshes often to reduce burn-in.

Scenario E: Short-Term Displays / Demo Devices

Choose: AMOLED if budget allows and lifetime is not critical.

4. Practical Engineering Tips

If you use AMOLED:

Avoid static images.

Add small UI movements or screen savers.

Reduce long-term max brightness.

Prepare spare modules for replacement.

If you use TFT:

Pick industrial-grade panels with wide temperature support.

Use brightness control to save power.

Add anti-glare or anti-reflective coatings for better readability.

Add protective glass for impact resistance.

5. Total Cost of Ownership (TCO)

The cost of a display includes more than the panel price.

You also need to consider:

replacement frequency

downtime when the screen fails

certifications

long-term supply support

TFT usually offers lower TCO for long-running industrial devices.

AMOLED offers better visuals but higher long-term maintenance cost.

6. Future Trends

1) Mini-LED and Local Dimming TFT

These new TFT technologies add higher contrast while keeping strong outdoor visibility and reliability.

2) Micro-LED

This may become the ideal industrial display in the future:

self-emitting, long lifetime, no burn-in.

But the cost is still very high.

3) Improved AMOLED Materials

Burn-in control algorithms and better OLED materials continue to improve, but not enough to fully match industrial 24/7 requirements today.

7. Final Conclusion

or long lifetime, stable 24/7 operation, and harsh environments → choose TFT-LCD.

For short-term use, high contrast, and modern visuals → choose AMOLED.

For mixed needs → watch Mini-LED and Micro-LED developments.

This gives engineers a clear and practical path when choosing a display for industrial products.