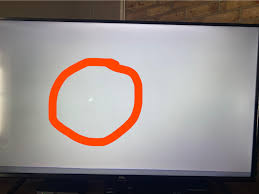

Have you ever noticed a tiny white dot on your phone, computer, or TV screen? Even if it’s the size of a pinhead, it stands out against a black background — this is what the industry calls a “white spot.” Though it may seem minor, a small flaw can have a significant impact depending on the usage scenario. Let’s discuss the standards, causes, and how factories deal with these tiny imperfections.

1. Different Requirements for White Spot Sizes in Various Scenarios

The use cases for displays are diverse, and the acceptable size of white spots varies significantly depending on the viewing distance, seriousness of the usage, and the user’s expectations for perfection. Generally, the industry standard is 0.2cm, and anything below this is considered a special requirement.

In-Car Displays: 0.2cm is the “safety threshold.” For in-car screens (e.g., center consoles or dashboards), which directly impact driving safety, any noticeable white spot can distract the driver. The driver frequently shifts attention between the screen and the road, so no spot larger than 0.2cm is allowed. Some car manufacturers even demand “zero white spots” across the entire display to ensure clarity of key information like speed and navigation.

Industrial & Medical Displays: “Anything over 0.2cm is scrap.” Displays in industrial control (e.g., machine control panels) and medical equipment (e.g., monitors, ultrasound screens) need to show precise data or images. A white spot could be misinterpreted as a defect or mask critical data. The standard here is strict: a single white spot should not exceed 0.2cm, and no spot should appear in core display areas. If a spot is larger than 0.2cm or more than one is present, we will see it as defective and scrapped.

Large Screens & High-Brightness Displays: White spots are more noticeable on large screens. At a distance of over 1 meter, tiny spots (like 0.1cm) may go unnoticed, but spots larger than 0.2cm become glaring. Large-screen standards usually allow a few spots between 0.1cm and 0.2cm, but anything over 0.2cm is unacceptable, and spots must not cluster together.

2. Where Do White Spot Come From? The Three Main Causes

White spots happen when certain pixels on the display don’t function properly, causing them to continuously emit light (resulting in a white or color-shifted spot). Production issues is the main reasons.

Foreign Object Contamination:

Tiny dust particles, metal fragments, or fibers can enter the production process and interfere with light transmission or the alignment of liquid crystals, leading to white spots. This is why panel factories maintain a very high level of cleanliness (typically in Class 1000 or Class 100 clean rooms). Even dust as small as 0.01mm can “seed” a white spot.

Manufacturing Defects:

In processes like photolithography or panel sealing, if the electrodes are misaligned or if there’s an issue with local voltage, some liquid crystals fail to rotate correctly, creating a permanent white spot. The size of the spot is often linked to the precision of the manufacturing process—higher precision (e.g., micron-level calibration) reduces the chance of defects.

External Damage:

During cutting or module assembly, slight pressure or impact may deform the backlight layer or crack the liquid crystal layer, forming a white spot. The size of these spots varies, and

they may change with temperature, but they are still caused by insufficient control over minor damage during production.

3. How Do Manufacturers Eliminate White Spot?

Reducing the occurrence of white spots is a key aspect of a display manufacturer’s quality competitiveness. Leading companies take three main approaches to lower white spot rates:

Extreme Cleanliness:

The factory cleanroom grade is upgraded from Class 1000 to Class 100 or even Class 10. Airflow systems, anti-static equipment, and fully automated conveyors minimize dust and contamination caused by human interaction. Some companies control room humidity between 40-60% to reduce static and dust buildup.

Process Upgrades:

To counter flaws with precision, companies use high-precision photolithography equipment (such as nano-level exposure machines) to control electrode alignment within 0.1 microns. In the sealing process, “vacuum lamination technology” is used to avoid air bubbles and impurities. AI vision inspection systems in production can detect even the smallest white spots (down to 0.05cm in diameter) and remove defective units immediately.

End-to-End Quality Control:

Strict inspections are conducted at every stage. From the raw materials (like glass substrates and liquid crystal materials) to in-process checks, and finally, full black-screen high-resolution photography before shipping, manufacturers ensure that white spots are kept below 0.1% (for premium products, even below 0.01%). For car displays, simulations of driving environments (e.g., strong light, low light) test the visibility of white spots from the driver’s perspective to ensure there are no defects.

Conclusion

The “perfection” of a display relies on controlling minute details like 0.1cm and 0.2cm. The ability of a manufacturer to control white spots, which is a direct indicator of their technical strength and commitment to quality.

Next time you light up your screen, notice how those “nonexistent” white spots never appear. Their absence is the result of countless careful steps in production.