As devices continue to move toward slimmer designs, higher integration, and better optical performance, In-cell touch displays have become an increasingly popular choice across industrial, medical, and commercial applications.

By integrating the touch sensor directly into the LCD pixel layer, In-cell technology offers clear advantages in thickness, weight, and optical quality. However, despite these benefits, many projects encounter challenges during real-world implementation—particularly when it comes to touch IC tuning and application-specific performance optimization.

What Is an In-cell Touch Display?

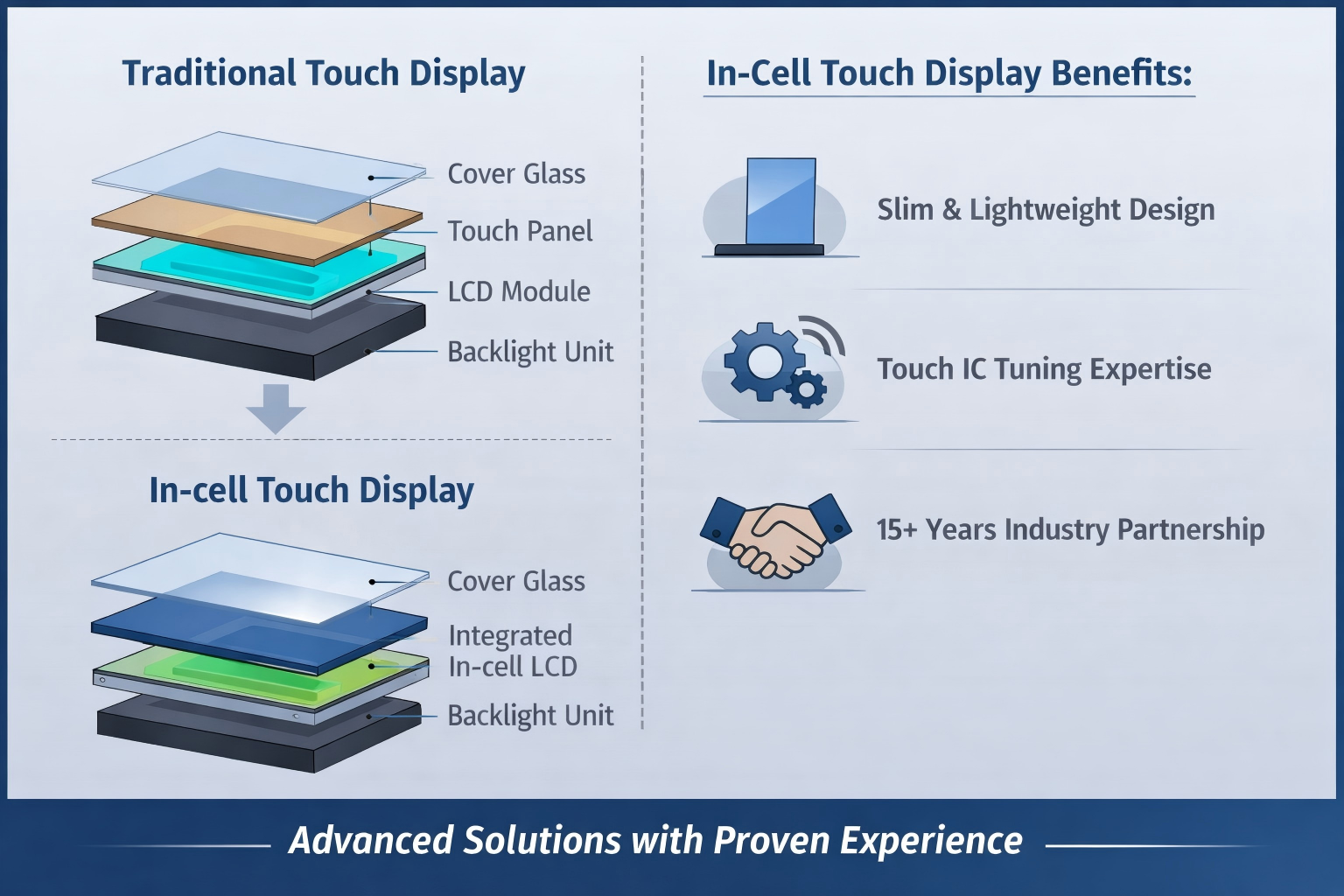

In an In-cell touch display, the touch sensing electrodes are embedded directly within the LCD structure, eliminating the need for a separate touch panel layer. Compared with traditional LCD + TP solutions or On-cell structures, In-cell technology enables a more compact and integrated module design.

This architecture is especially attractive for applications that require:

Slim and lightweight form factors

High optical clarity

Reduced assembly complexity

Key Advantages of In-cell Touch Displays

1. Slimmer and Lighter Module Design

By removing the additional touch panel layer, In-cell displays significantly reduce overall module thickness and weight. This makes them ideal for space-constrained designs such as handheld terminals, compact HMIs, and modern control panels.

2. Improved Optical Performance

Fewer layers mean less internal reflection and light loss. In-cell displays typically offer:

Higher contrast

Better sunlight readability

Cleaner image quality

These benefits are particularly important for outdoor, industrial, and medical environments.

3. Lower System-Level Cost

Although the panel itself may appear more integrated, In-cell solutions often reduce total system cost by:

Eliminating additional touch components

Simplifying assembly and bonding processes

Improving yield consistency in mass production

4. Enhanced Reliability

A simpler structure means fewer interfaces where failures can occur. In-cell displays generally show better resistance to vibration, shock, and long-term aging—key requirements in industrial and professional applications.

The Real Challenge: Touch IC Tuning Across Different Applications

While the advantages of In-cell displays are clear, touch performance is not a “plug-and-play” feature.

In real projects, touch behavior is highly dependent on:

Application environment (industrial noise, moisture, gloves, water)

Cover glass thickness and material

Cover glass thickness and material

EMI/EMC conditions

User interaction patterns

As a result, the touch IC must be carefully tuned and optimized for each specific application scenario. This process often requires multiple iterations of parameter adjustment, firmware refinement, and validation testing.

Without close cooperation between the display supplier and the touch IC manufacturer, projects may face:

Unstable touch response

False touch or missed inputs

Long debugging cycles

Delayed project timelines

Why Upstream Collaboration Matters

Successfully deploying an In-cell touch display is not just about selecting the right panel—it depends heavily on the depth of upstream cooperation.

With over 15 years of experience in the display industry, our company has built long-term, stable partnerships with leading touch IC manufacturers. This allows us to:

Access IC-level technical support early in the project

Customize touch parameters for different application environments

Rapidly resolve noise, sensitivity, and compatibility issues

Shorten development and validation cycles

Instead of treating touch tuning as a post-production problem, we integrate touch IC optimization into the early design stage, ensuring stable performance before mass production.

Our In-cell Display Solutions in Practice

Based on this experience, we have developed multiple In-cell display solutions covering different sizes, resolutions, and brightness levels. These solutions are designed to support industrial-grade and commercial applications where touch stability and long-term reliability are critical.

By leveraging our upstream resources and engineering experience, we help customers move from concept to production with fewer risks and faster time-to-market.

When Should You Choose an In-cell Touch Display?

An In-cell touch display is an excellent choice if your project:

Requires a slim, integrated design

Prioritizes optical performance

Targets medium to high production volumes

Operates in complex or noisy environments

Needs customized touch behavior rather than generic settings

Final Thoughts

In-cell touch displays offer clear structural and optical advantages, but their true value is only realized when touch performance is carefully engineered for the real application environment.

Choosing a display partner with deep industry experience and strong upstream collaboration can make the difference between a smooth product launch and prolonged debugging cycles.

If you are evaluating In-cell touch displays for your next project, our team would be happy to provide technical consultation and tailored recommendations.