With an 800x480 resolution, the 5 inch LCD screen operates steadily within a wide temperature range of -30℃ to 80℃. Boasting a high brightness of 1000 nits and IPS wide viewing angles, it is ideal for automotive and industrial control applications. Upon seeing these specifications, you might assume this LCD screen comes with a hefty price tag. Indeed, screens with similar configurations from renowned brands like AUO and Innolux are typically expensive. Considering the cost control needs of many businesses, we have developed this high-performance yet budget-friendly 5-inch LCD screen. Its price is less than half, and in some cases, nearly one-third of the original branded screens.

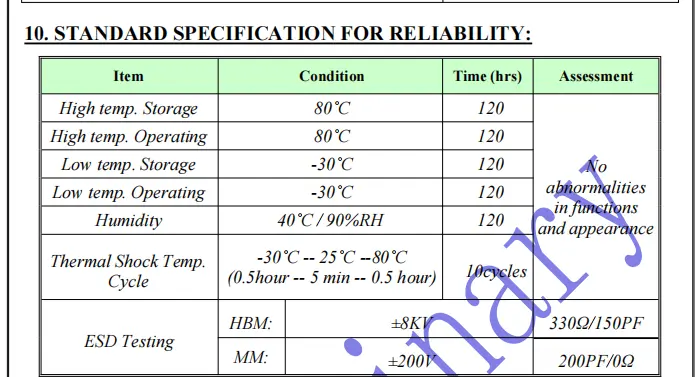

However, you may wonder: with such significant cost savings, does the screen compromise on stability? The image above illustrates our stringent reliability test standards. This screen has been in mass production for two years, supplying to automotive clients. According to customer feedback, it performs remarkably well with an impressively high yield rate.

Now, let's explore the technical strategies behind our cost control approach.

Optimization of Core Component Costs

Backlight Solution Selection

LED Bead Optimization: We use domestic high-brightness LED beads, reducing the cost per bead by 30% compared to imported brands. Through precise optical design, we compensate for brightness uniformity. In the 5 inch LCD screen, four LED beads are arranged in a straight line, paired with a high-reflectivity light guide plate (reflectivity ≥95%). This setup achieves a brightness uniformity of ≥85% at 1000 nits.

Simplified Driver Circuit: We abandon the dynamic backlight zoning solution and adopt a constant current driver circuit, slashing material costs by 40%. With PWM dimming, we balance brightness and power consumption. Under wide-temperature conditions (-30℃ to 85℃), the brightness fluctuation remains within ≤5%.

Material Innovation for Wide-Temperature Backlight

The adhesive used in the backlight module is a domestic low-temperature curing adhesive. It reduces the curing temperature from 150℃ to 80℃, cutting energy consumption costs by 25%. Even at -40℃, it maintains elasticity, preventing backlight failures caused by low-temperature cracking.

Selection of Glass Substrate: Yield Assurance with Innolux's Industrial-Grade Solution

Economies of Scale from Mature Production Lines

We choose Innolux's 5-inch Class A glass. Leveraging the advantages of their 5.5th generation TFT-LCD production line, the cost of the glass substrate is 22% lower than that of smaller manufacturers, while the panel defect rate is less than 0.1%. The glass surface is coated with a dual-layer AR/AG film (transmittance ≥92%, haze 3%). Using Innolux's exclusive magnetron sputtering process, the film adhesion reaches Class 5B, reducing costs by 15% compared to traditional spraying processes and enhancing outdoor anti-reflection capabilities.

Native Design for Wide-Temperature Performance

The liquid crystal cell thickness of Innolux's glass is precisely controlled at 5μm±0.2μm. Combined with negative liquid crystal materials, the response time at -30℃ is ≤30ms (compared to >50ms for ordinary glass). This eliminates the need for additional heating circuits, saving 5 yuan per screen.

In summary, we cut costs where possible, but for critical components like glass that determine performance, we prioritize high cost-effectiveness. If you're in search of a cost-effective 5-inch LCD screen, give ours a try. The interface is customizable, and touch solutions are available. Samples can be shipped at any time.