As a small-to-medium enterprise with 15 years of deep expertise in the LCD touch screen industry, we have delivered hundreds of LCD touch solutions across diverse application scenarios—from consumer electronics to industrial manufacturing and medical devices. Almost all are customized projects. Today, we analyze a case study to help you understand the customization process and cost breakdown of touch screens.

Consumer Electronics Touch Screen Customization Case

The end client is a water purifier manufacturer who partnered with us (Zhongyou Touch Display) in 2023. Initially, we confirmed the module specifications: size, interface, etc. After finalizing the module, we began to assess the core requirements and feasibility of the touch screen, including: dimensions, interface, and selection of the touch IC (which determines touch accuracy).

Once the client’s requirements were confirmed, the client provided us with the touch screen part based on their overall equipment drawings. Our engineering team refined the drawings, annotating requirements and materials on the touch screen diagram for the client’s final approval. After confirmation, our sales team issued a final quotation. Upon the client’s approval, we proceeded to production.

As shown in the diagram, the final touch screen features a perforated panel (cover glass) with 4 through-holes. This shape requires custom tooling (cover glass tooling), with costs depending on complexity—approximately RMB 2,000–3,000 for this case.

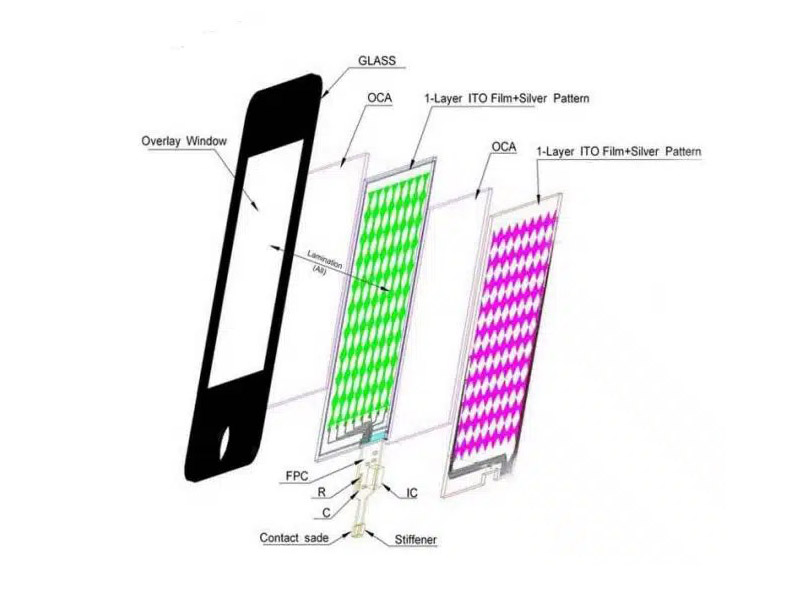

The internal structure is not easily visible, I put a touch-screen structure for better understanding. The ITO layer (sensor part), which determines touch functionality, also requires customization, typically starting at RMB 3,000 in the domestic market.

FPC (flexible printed circuit) cables also need customization, as the wiring varies by device’s internal structure (shape, length, interface). FPC customization costs range from RMB hundreds to thousands, depending on complexity.

This is a relatively simple touch screen customization project but covers most common tooling fees in touch screen customization. Tooling costs vary by complexity, and manufacturers generally do not profit from tooling fees—they may even be refundable for large orders. Below is a brief summary of the customization process:

Clarify Core Requirements: Define technical specifications (e.g., size, touch accuracy) and functional integration.

Design & Prototyping:

Hardware Design: Structural design (thickness, mounting holes, FPC routing), circuit design, touch IC selection, material selection (glass type, touch film process).

Software Adaptation: Collaborate with IC manufacturers to debug software.

Sample Production & Testing: Produce 1–3 samples for functional testing (sensitivity, drift rate), environmental testing (temperature, vibration, waterproofing), and compatibility testing.

Mass Production: Begin production after sample approval.

https://displaysell.com/product-category/other-products/capacitive-touch-screen