Many blog posts are good at comparing resistive and capacitive touch screens. In fact, we are not trying to compare which is better; we need to understand how to apply resistive and capacitive touch screens in our projects. This article will take you through their development history, technical principles, and application fields. Then help us gain a deeper understanding of the touch industry.

1. Technical Origins

The birth of resistive touch screens was quite accidental. In 1971, Professor Sam Hurst from the University of Kentucky. Accidentally discovered, that pressure could change the current transmission path while researching electron microscopes, thus inventing resistive touch technology.

The theoretical exploration of capacitive touch screens started earlier. In 1965, British engineer Eric Arthur Johnson published a paper in Electronics Letters proposing the principle of capacitive sensing. However, limited by material technology, the LG KE850 Prada mobile phone first mass-produced capacitive screens. What truly popularized capacitive screens was the release of the iPhone in 2007; its multi-touch experience redefined mobile interaction. This technology, based on human body electric field coupled capacitance, completely subverted the single-touch mode of resistive screens.

2. Technical Principles

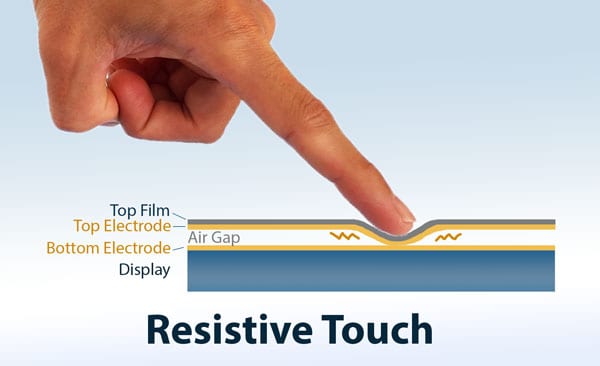

Resistive screens adopt a multi-layer composite structure. The base glass is coated with an ITO conductive layer. The surface is covered with a plastic film with a conductive coating. The two layers are separated by micron-level insulating dots. When pressed by a finger, the two ITO layers come into contact, causing a resistance change. The coordinate is located by measuring the voltage difference through a four-wire or five-wire circuit. This design allows it to be touched by any object, including gloves, styluses, and even in humid environments. However, the multi-layer structure results in a light transmittance of only 75%, and long-term use may reduce accuracy due to wear.

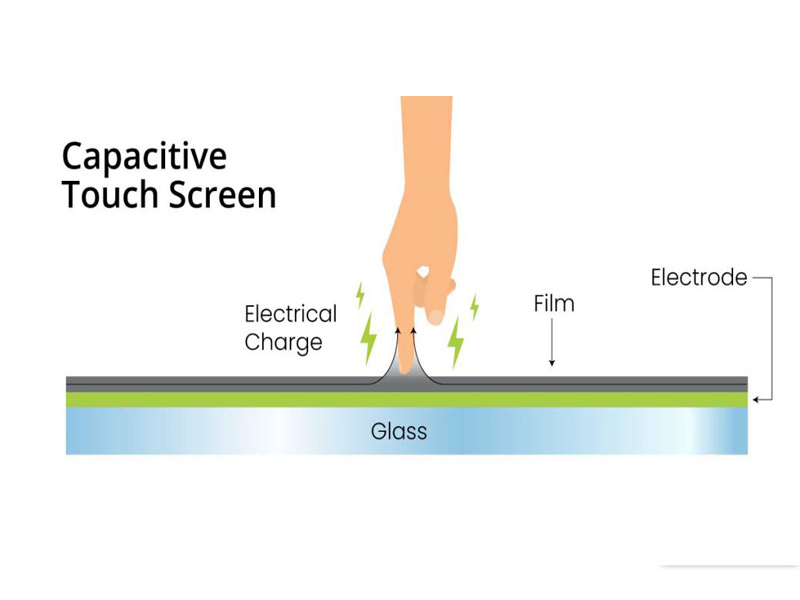

Capacitive screens are based on four-layer composite glass: an outer tempered glass protective layer, two middle ITO conductive layers forming a mutual capacitance matrix, and an inner ITO layer as a shielding layer. When a finger approaches, the human body's charge changes the coupled capacitance value, and the controller calculates the coordinate by detecting the current ratio of row and column electrodes. Mutual capacitance technology enables multi-touch; by independently scanning each electrode intersection, multiple touch points can be identified simultaneously. However, capacitive screens rely on human conductivity and fail when using regular gloves or in humid environments.

3. Application Scenarios

Resistive Screens in Industrial Control

In factory workshops, resistive screens withstand oil, dust, and mechanical vibrations. Their ability to operate with gloves makes them a standard for machine tool control panels.

In medical equipment, resistive screens’ IP67 protection meets the needs of frequent disinfection in operating rooms, while capacitive screens’ glass surfaces easily corrode from chemical cleaners.

In outdoor scenarios, resistive screens work stably at -20℃, while capacitive screens drift due to temperature changes.

Latest market reports project the global resistive TFT touch display market will reach $35 billion by 2025, with industrial control accounting for over 40%.

Capacitive Touch Screens in Consumer Electronics

In the automotive field, the high light transmittance of capacitive screens ensures clear display even in strong light, while the multi-layer structure of resistive screens causes screen reflection. In smart homes, the low power consumption of capacitive screens (<1mW) makes them more advantageous in battery-powered devices, such as smart door locks and central control panels. It is reported that the compound annual growth rate of capacitive screens in the industrial control field will reach 15% by 2025, mainly used in robot operation interfaces and smart instruments.

These two technologies are like two sides of a coin: resistive screens safeguard the industrial foundation with mechanical reliability, while capacitive screens lead consumer trends with interactive innovation. Their development history is not only a chronicle of technological iteration but also a continuous exploration of the interaction between the physical world and the digital space. In today's world where smart devices permeate every corner, understanding their technical essence and scenario adaptation logic is the key to achieving optimal solutions in product design.

Hangzhou Zhongyou Touch Display has specialized in touch display for over a decade. Whether you need resistive touch, capacitive touch, or the currently popular Incell touch, we can find the optimal solution for you.