"Your unit price is very cheap—half the cost of that original supplier—but why do I need to pay for mold fees?"

"Why can’t I just buy directly instead of paying for custom molds?"

These are the most common questions I hear from small and medium-sized enterprises (SMEs), especially overseas buyers newly entering the display industry. Many are unaware of the supply chain dynamics in displays or what exactly mold fees cover. Today, let’s demystify why most touch screens require custom molds and break down the costs involved.

Why is it hard to find universal touch screens?

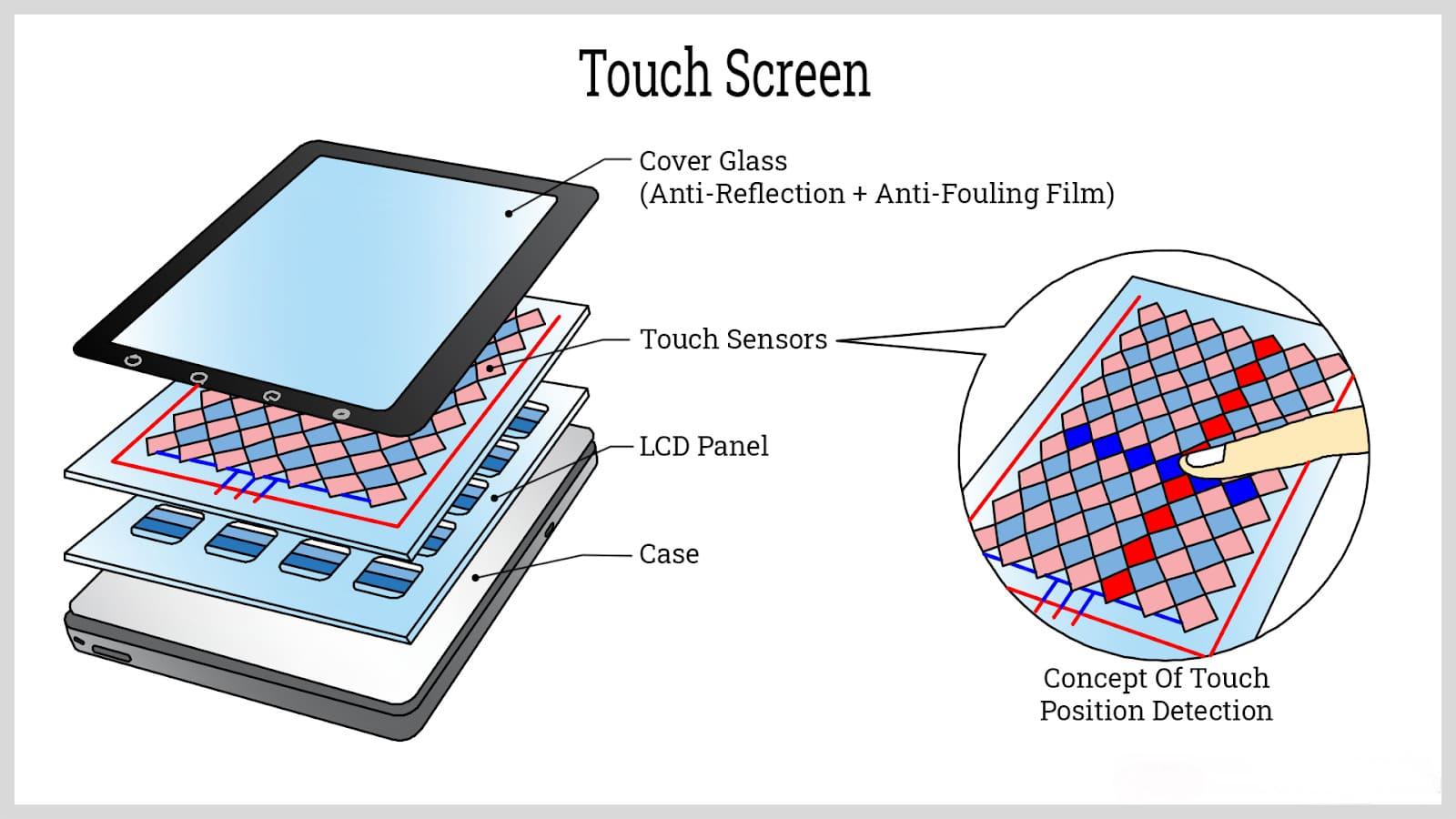

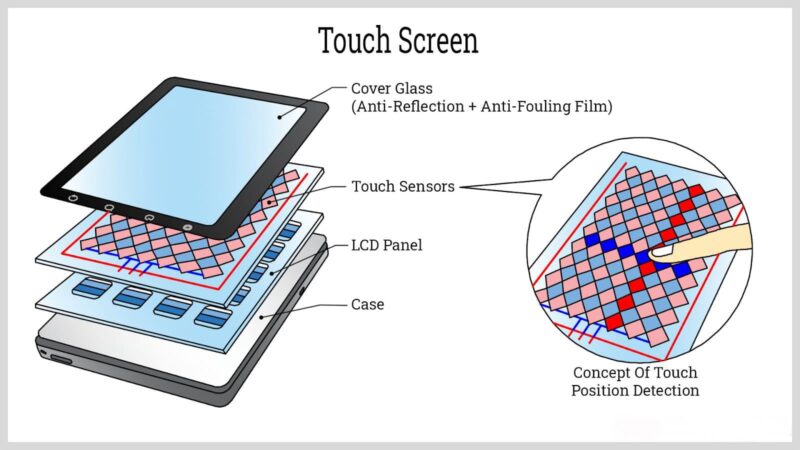

First, let’s explore why touch screens can’t be as universal as display panels. The inability to universalize touch screens fundamentally stems from the complexity of their technical characteristics, business ecosystems, and application scenarios. For example:

- Material differences impact touch performance, sensitivity, and display quality;

- Size and specifications affect how touch screens connect to display panels;

- Industry-specific adaptations (e.g., medical devices needing compatibility with medical gloves, requiring dedicated "glove mode" touch functions);

- Extreme differentiation in application scenarios (industrial scenarios demand extremely high product reliability at costs unattainable for consumer electronics);

- Experience-driven differentiation in consumer electronics has become the norm in the business landscape.

Touch screens are rarely found is because of these reasons.

Must custom touch screens require mold opening?

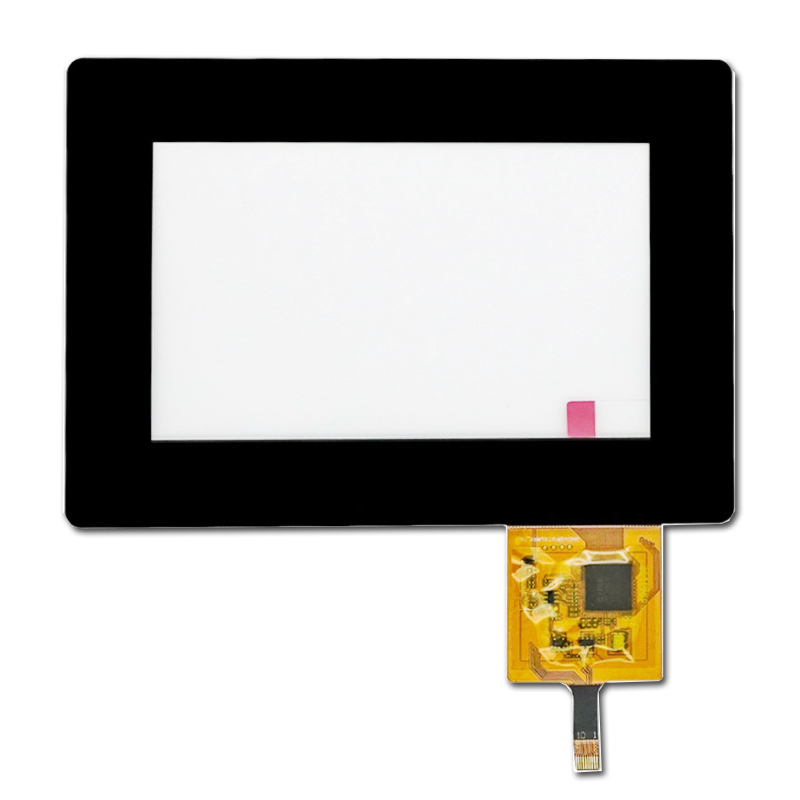

Many touch screens used for specific devices and application scenarios, making identical off-the-shelf products scarce. Due to differences in devices, the customization process often requires redesigning glass structure dimensions and flex cable interface definitions to ensure seamless integration with your device. This is where mold opening becomes necessary, involving injection molds, glass molds, and FPC (flexible printed circuit) molds. Manufacturers will assess which molds are needed based on the device’s specifications.

What modules are included in touch screen mold fees?

When manufacturers quote mold fees, the cost encompasses more than just the physical molds. It typically includes the following components, each influenced by factors like technical complexity, material selection, and process precision:

- Mold design fees

- Basic design costs: Includes 3D modeling, mold flow analysis, and manufacturability optimization fees.

- Customization premiums: Additional structural design fees for special-shaped screens (e.g., curved screens with R≤3mm) or molds with special functions (e.g., pressure sensitivity).

- Mold material fees

- Substrate costs: Materials for injection molds, glass molds, FPC molds, etc.

- Surface treatment costs: Nitriding to enhance mold hardness, hard chrome plating to improve wear resistance, etc.

- Processing and manufacturing fees

- Debugging and validation fees

- Other hidden costs

Touch screen mold fees represent a technology-intensive investment, with processing and material costs accounting for over 80%, while design, debugging, and patent costs are significant hidden expenses. Enterprises should comprehensively evaluate these based on product positioning (consumer vs. industrial), production scale (small batch vs. mass production), and technical requirements (precision/functionality).

That’s all for today’s sharing. After reading this, do you still think mold fees are unreasonable? Displaysell is a company specializing in integrated display and touch solutions. Regardless of your enterprise’s size or industry, we are committed to providing you with the best display and touch solutions with our top-tier service and sincere attitude.