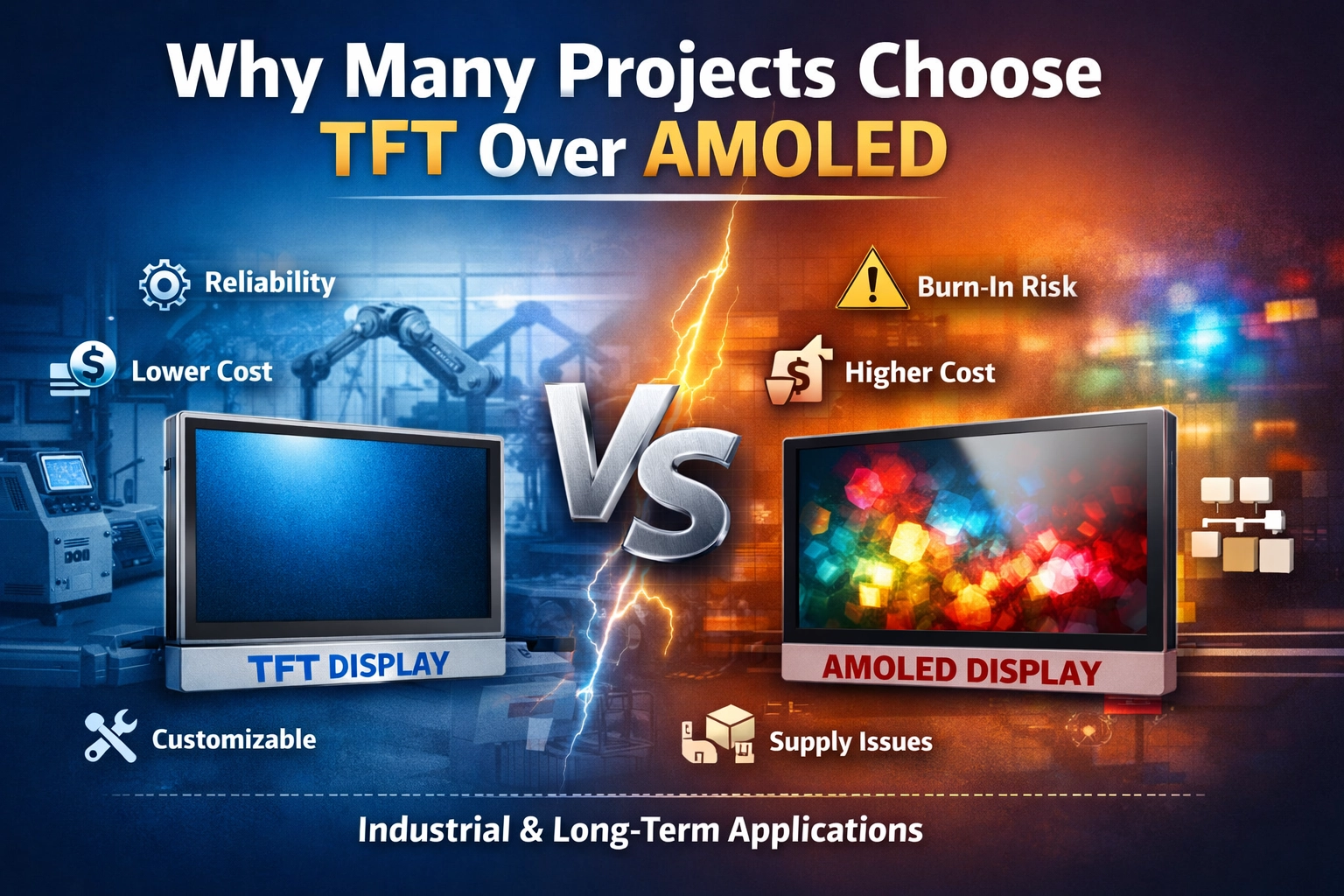

When comparing display technologies, AMOLED often attracts attention with its vivid colors, high contrast, and sleek appearance. However, in real-world projects—especially industrial, medical, and commercial applications—many projects ultimately choose TFT LCD instead of AMOLED.

Why does this happen?

Beyond visual performance, project success depends on stability, lifespan, cost control, customization flexibility, and long-term supply reliability. This article explains the key reasons why TFT remains the preferred choice for many professional display projects.

Stability and Long-Term Reliability Matter More Than Visual Impact

While AMOLED is a self-emissive technology, it also introduces aging and burn-in risks, especially in applications where static images are displayed for long periods.

TFT LCD displays, on the other hand, offer:

1-Stable brightness over long operating hours

2-No burn-in risk for static UI or fixed layouts

3-Proven performance in 24/7 operation environments

For industrial HMIs, medical devices, instrumentation, and control panels, long-term reliability often outweighs visual aesthetics.

Longer Product Lifespan and Consistent Performance

Many professional projects require a product lifecycle of 5–10 years or longer. TFT displays are well known for:

Predictable aging behavior

Consistent color and brightness over time

Easier qualification and revalidation during product updates

In contrast, AMOLED panels may suffer from uneven pixel degradation, which can affect long-term visual consistency and increase maintenance or replacement costs.

Lower Overall Cost and Better Cost Control

Although AMOLED prices have decreased in recent years, TFT still offers a more cost-effective solution, especially for medium and large-size displays or customized projects.

From a project perspective:

TFT module cost is generally lower

Driver IC and system integration are more mature

Yield rates and sourcing options are more stable

For projects sensitive to BOM cost and long-term pricing stability, TFT provides better overall cost control.

Greater Customization Flexibility

Customization is a critical requirement for many B2B projects. TFT displays offer strong flexibility in:

Size and aspect ratio

Interface options (RGB, LVDS, MIPI, SPI, etc.)

Brightness levels and wide-temperature operation

Touch integration (capacitive or resistive)

Surface treatments such as AG, AR, or AF

AMOLED solutions, by comparison, are often more standardized and less flexible, especially for small to mid-volume customized projects.

More Reliable Supply Chain for Long-Term Projects

Supply continuity is a key risk factor in professional projects. TFT displays benefit from:

A broader supplier ecosystem

Multiple panel and IC alternatives

Better long-term availability for repeat orders

AMOLED production is more concentrated, which can introduce higher supply risk, longer lead times, or sudden model discontinuation. For projects requiring stable delivery over many years, TFT is often the safer option.

TFT Is Often the Practical Choice for Industrial and Commercial Applications

Despite AMOLED’s visual advantages, TFT LCD remains the practical and proven solution for many applications, including:

Industrial control systems

Medical equipment

Smart home panels

Outdoor and high-brightness devices

Automotive and transportation displays

In these scenarios, reliability, customization, and lifecycle management are far more critical than ultra-high contrast or saturated colors.

Conclusion

AMOLED excels in consumer electronics where visual impact is the top priority. However, for industrial, medical, and long-term commercial projects, TFT displays continue to be the preferred choice due to their stability, lifespan, cost efficiency, customization flexibility, and reliable supply chain.

Understanding your application requirements is the key to choosing the right display technology—and in many real-world projects, TFT proves to be the smarter, safer decision.