As an LCD manufacturer with over 15 years of experience supplying TFT displays for industrial, outdoor, and embedded applications, we often see the same issue repeated across different projects:

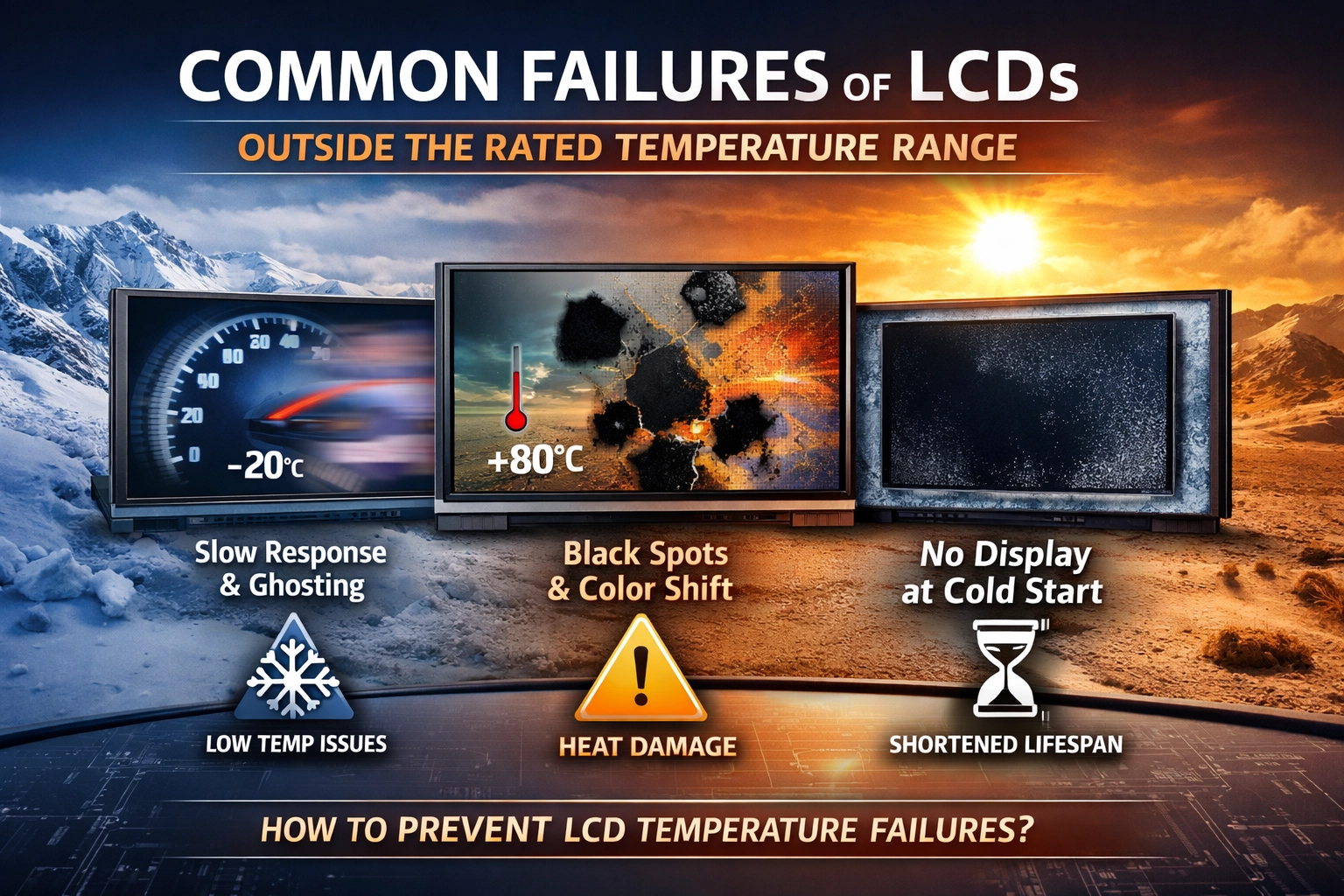

the LCD is used outside its rated temperature range.

In many cases, the display itself is not “defective.” Instead, it is operating in an environment it was never designed for. This article explains the most common LCD failures caused by temperature mismatch, why they happen, and—more importantly—how to avoid them at the design stage.

Why the Rated Temperature Range of an LCD Is Critical

The Liquid Crystal Display temperature range defines the environmental conditions under which the display can maintain stable optical performance and long-term reliability.

When an LCD operates outside this range, problems may appear immediately or gradually over time, including:

Slow or incomplete image response

Contrast and color shift

Permanent image artifacts

Shortened product lifespan

From a factory perspective, temperature-related failures account for a large percentage of post-deployment display issues, especially in industrial and outdoor products.

Common LCD Failures at Low Temperatures

Slow Response Time and Image Smearing

At low temperatures, liquid crystal molecules become more viscous. This directly leads to:

Slow pixel response

Motion blur or smearing

Ghosting during screen transitions

This is frequently observed when standard temperature LCDs (0~50°C) are used in environments below freezing.

How to avoid it:

Select wide-temperature LCDs (e.g. -20~70°C or -30~80°C)

Use liquid crystal materials optimized for low-temperature response

Validate performance during cold-start testing, not only steady-state testing

Display Does Not Turn On at Cold Start

In extremely low temperatures, some LCDs may appear “dead” during power-up. This is usually caused by:

LC material not responding fast enough

Driver IC timing mismatch at low temperature

How to avoid it:

Choose displays with verified cold-start performance

Confirm the operating temperature range, not only the storage range

Work with manufacturers who conduct real low-temperature power-on tests

Common LCD Failures at High Temperatures

Contrast Degradation and Color Shift

High temperatures accelerate molecular movement in liquid crystal materials, resulting in:

Reduced contrast ratio

Washed-out colors

Inconsistent grayscale performance

This issue is common in outdoor, enclosed, or sun-exposed devices where internal temperatures rise significantly.

How to avoid it:

Use high-temperature LC formulations

Select polarizers rated for elevated temperatures

Evaluate optical performance at maximum operating temperature, not just room temperature

Permanent Black Spots or Image Non-Uniformity

Prolonged exposure to temperatures above the rated limit may cause:

Irreversible damage to liquid crystal alignment

Polarizer shrinkage or deformation

Localized dark or bright spots

These failures are often permanent and non-repairable.

How to avoid it:

Maintain adequate thermal design (ventilation, heat spreading)

Avoid placing the LCD near heat sources (CPU, power modules)

Choose displays with proven high-temperature aging data

Long-Term Reliability Issues Caused by Temperature Stress

Accelerated Aging and Reduced Lifespan

Even if an LCD appears functional outside its rated temperature range, long-term operation may lead to:

Faster brightness decay

Early backlight failure

Increased risk of field returns

From a manufacturing standpoint, this is one of the most underestimated risks.

How to avoid it:

Design with sufficient temperature margin

Conduct thermal cycling and aging tests

Partner with suppliers who understand both LC materials and backlight reliability

How Experienced LCD Manufacturers Prevent Temperature-Related Failures

As a TFT LCD factory, temperature reliability is not addressed by a single component—it requires system-level coordination, including:

Liquid crystal material selection

Polarizer and optical film matching

Driver IC compatibility

Backlight thermal management

Process control and validation testing

Displays designed for wide-temperature operation are not simply “standard panels with a wider label”. They require deeper material knowledge and manufacturing experience.

Choosing the Right LCD Temperature Range for Your Application

Before selecting an LCD, we recommend answering these questions:

What is the real operating temperature inside the enclosure?

Is cold-start performance required?

Is the product exposed to direct sunlight or enclosed heat sources?

What is the expected product lifetime?

Answering these early can prevent costly redesigns later.

Final Thoughts from the Manufacturer’s Perspective

Operating an LCD outside its rated temperature range is one of the most common—and avoidable—causes of display failure.

With proper selection and early collaboration, most temperature-related issues can be eliminated before mass production.

If your application involves industrial, outdoor, or harsh environments, choosing the correct Liquid Crystal Display temperature range is not optional—it is essential.