As a core component of various electronic devices, the quality of LCD modules directly affects the user experience. During production, transportation, or use, some defects are inevitable. This article will detail common appearance defects and functional defects, along with targeted solutions.

LCD modules-Appearance Defects and Solutions

1. Bright Spots for lcd

Phenomenon: Persistently glowing small dots appear on the screen, usually white or monochromatic, which are particularly noticeable against a black background.

Causes: Mainly due to damage to liquid crystal molecules or electrodes in pixel units during panel production, causing the pixel to remain conductive and luminous. Generally, if a single bright spot has a diameter exceeding 0.2mm or there are 3 or more bright spots on the same screen, it will significantly affect the visual experience.Solutions: In the production process, strictly conduct quality inspections in accordance with industry standards and reject products that exceed the allowable range; if bright spots are found during use and affect usability, the panel needs to be replaced.

2. Light Leakage

Phenomenon: Irregular light emission occurs at the edges or corners of the screen, which is more prominent when viewing black images in dark environments.

Causes: Mostly due to loose fitting between the frame and the panel during module assembly, resulting in gaps; it may also be that the panel itself has micro-cracks, causing backlight leakage.

Solutions: Optimize the assembly process to ensure tight fitting between the frame and the panel, and replace the sealing strips if necessary; strengthen incoming inspection of panels to prevent cracked panels from entering the production process.

3. Backlight Scratches

Phenomenon: Scratches appear on the surface of the backlight module, which may affect the uniform emission of light and are visible at specific angles.

Causes: Improper operation during production, such as tool scratches; insufficient protection during transportation, resulting in friction with hard objects.Solutions: Standardize production operation procedures, with staff wearing special gloves to avoid direct contact between tools and the backlight surface; use special packaging during transportation and add protective pads.

4. Foreign Objects

Phenomenon: There are impurities such as dust, fibers, and particles inside or on the surface of the screen.

Causes: Insufficient cleanliness in the production environment, incomplete cleaning before assembly; or loose packaging sealing, leading to foreign objects entering during transportation.Solutions: Improve the cleanliness level of the production workshop, strengthen the cleaning process for panels and modules; use packaging materials with good sealing performance and conduct a final inspection before packaging.

Functional Defects and Solutions

1.Display Abnormalities

Phenomenon: Display images show abnormalities such as distortion, discoloration, missing lines, and screen blooming.

Causes: Driver circuit failures, such as damaged driver ICs; interference or poor contact during signal transmission; open circuits or short circuits in the internal lines of the panel.Solutions: Inspect the driver circuit, repair or replace damaged driver ICs; ensure firm connection of signal interfaces and replace connecting wires if necessary; test the panel to repair or replace panels with line problems.

2. Black Screen

Phenomenon: The screen shows no display at all, presenting a black state.

Causes: Power supply failures, such as damaged power adapters or broken power supply lines; damaged backlight modules that cannot emit light; driver board failures that cannot output driving signals.

Solutions: Troubleshoot the power supply part, replace damaged power adapters or repair power supply lines; inspect the backlight module and replace damaged backlight components; repair or replace faulty driver boards.

3. Image Retention

Phenomenon: After displaying a fixed image for a long time, traces of the previous image remain on the screen when switching images.

Causes: Liquid crystal molecules remain in the same state for a long time, slowing down their recovery speed; the panel has been used for too long, leading to aging.

Solutions: Avoid displaying static images for a long time; set up automatic image switching or screen savers; select panels with good quality and strong anti-image retention performance to extend the service life of the module.

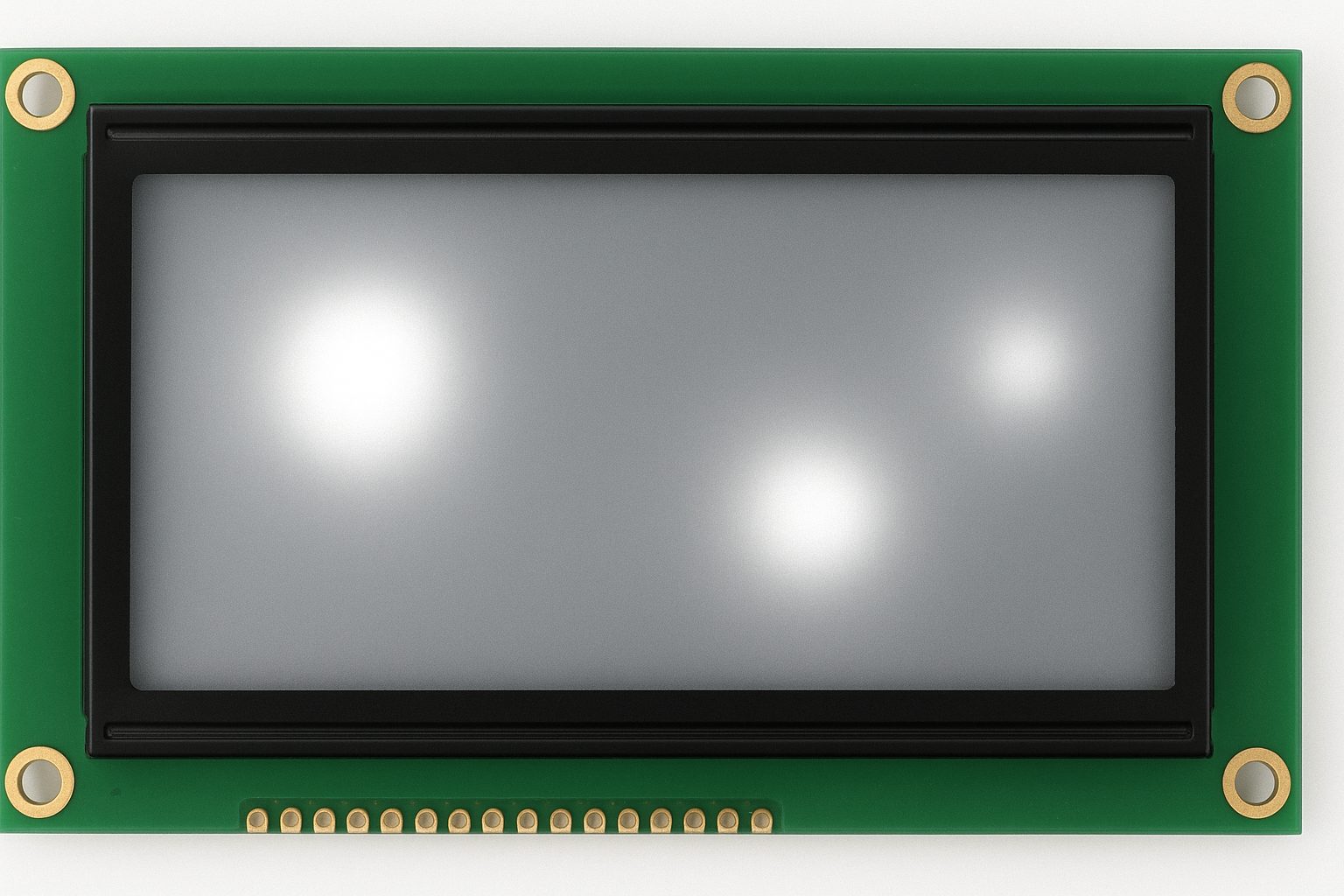

4. Mura

Phenomenon: Uneven light spots, shadows, or light/dark stripes appear in the display area, affecting the consistency of the image.

Causes: Closely related to the backlight module, such as uneven distribution of backlight sources, defects in the light guide plate; or uneven pressure on the panel, causing abnormal arrangement of liquid crystal molecules.

Solutions: Improve the design of the backlight module to ensure uniform distribution of light sources and select high-quality light guide plates; avoid squeezing or colliding with the panel during assembly and use.

Summary

Defects in LCD modules may be caused by various factors, requiring strict control over every link from production to use. By strengthening quality inspection, optimizing production processes, and standardizing operating procedures, the occurrence of defects can be effectively reduced. Once defects are found, timely analysis of causes and implementation of corresponding solutions can ensure the good performance and user experience of LCD modules.